This work (other than the webtool) has been published in this RIVM brochure

Calculation method background

We have used calculation methods from Rajagopalan et al (2021), and combined this with the data provided by the IEA factsheet using the updated data from the IEA PVPS life cycle inventory. We perform the analysis on a mono-Si PV system, since it is expected this technology will dominate the market in the short term future, and environmental data availability is much higher compared to other technologies.

In the IEA factsheet, for span of 30 years, the total carbon emissions per generated kWh for a mono-Si PV

system are 42.5 g CO2-eq, with the following scope and conditions:

- System: 3 kWp PV system, flat-roof installation in Europe, including panel, cabling, mounting structure, inverter and system installation

- Expected lifetime: 30 year for panels, 15 year for inverters

- Irradiation: 975 kWh/kWp

- Efficiency: 19.5% efficiency for mono-Si technology

- Degradation: 0.7% linear yield degradation

- Life cycle stages: manufacturing, transport, installation, use and end-of-life stage

- Global value chain: the LCA takes into account the global value chain behind the production of a PV system installed in Europe, and includes market mixes for sourcing regions for wafers, photovoltaic cells and panels.

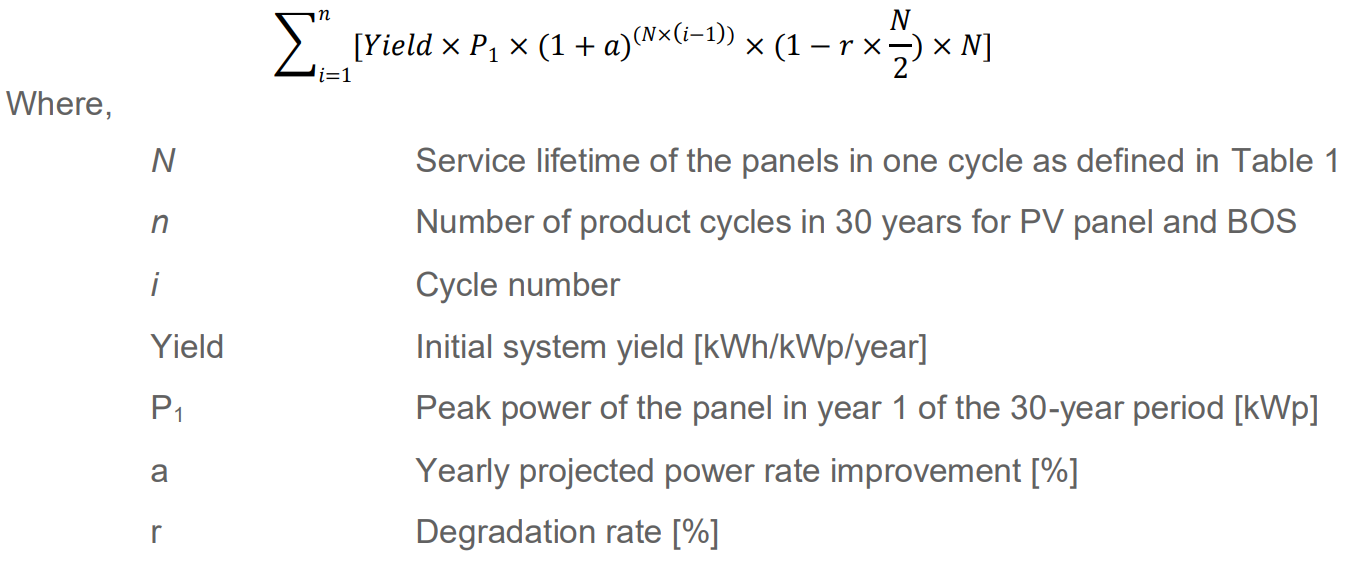

Rajagopalan et al (2021) provides an equation to calculate the yield for a PV system over a span of 30

years, including the effect of replacing panels before its expected lifetime (equation 1). With this

equation, we calculate the 30 year yield of the PV system described earlier: 78536 kWh. Together with the

carbon coefficient, we find that this system takes (42.5 g CO2-eq /kwh * 78536 kWh = ) 3337 kg CO2-eq per

panel (to produce, maintain, and discard the panel by recycling).

For the same system, we can calculate the carbon coefficient for an installation in the Netherlands. The

irradiation in the Netherlands is around 1044 kWh/kWp, so this

results in a

baseline of 39.7 g CO2-eq/kWh.

This result fall within the range of carbon coefficients calculated

by TNO, being 29 g CO2-eq/kWh and 55 g

CO2-eq/kWh for a system produced with a European and Chinese energy mix profile, respectively. This system

and its performance forms the baseline for this study.

With the given baseline, we can assess various replacement scenarios based on the equation 1 in

combination with the equation 2. In replacement scenarios, where the system will be

replaced with newer panels before its expected lifetime, it is necessary to take into account future

technological development (especially for the rapidly evolving PV technologies). Newer panels are usually

more efficient, and can have a lower carbon profile over its life cycle due to efficiencies in production or

higher circularity (e.g. higher material recycling or higher modularity). Equation 1 includes

a, the yearly projected power rate improvement (in %), which is expected to be around 1.4%.

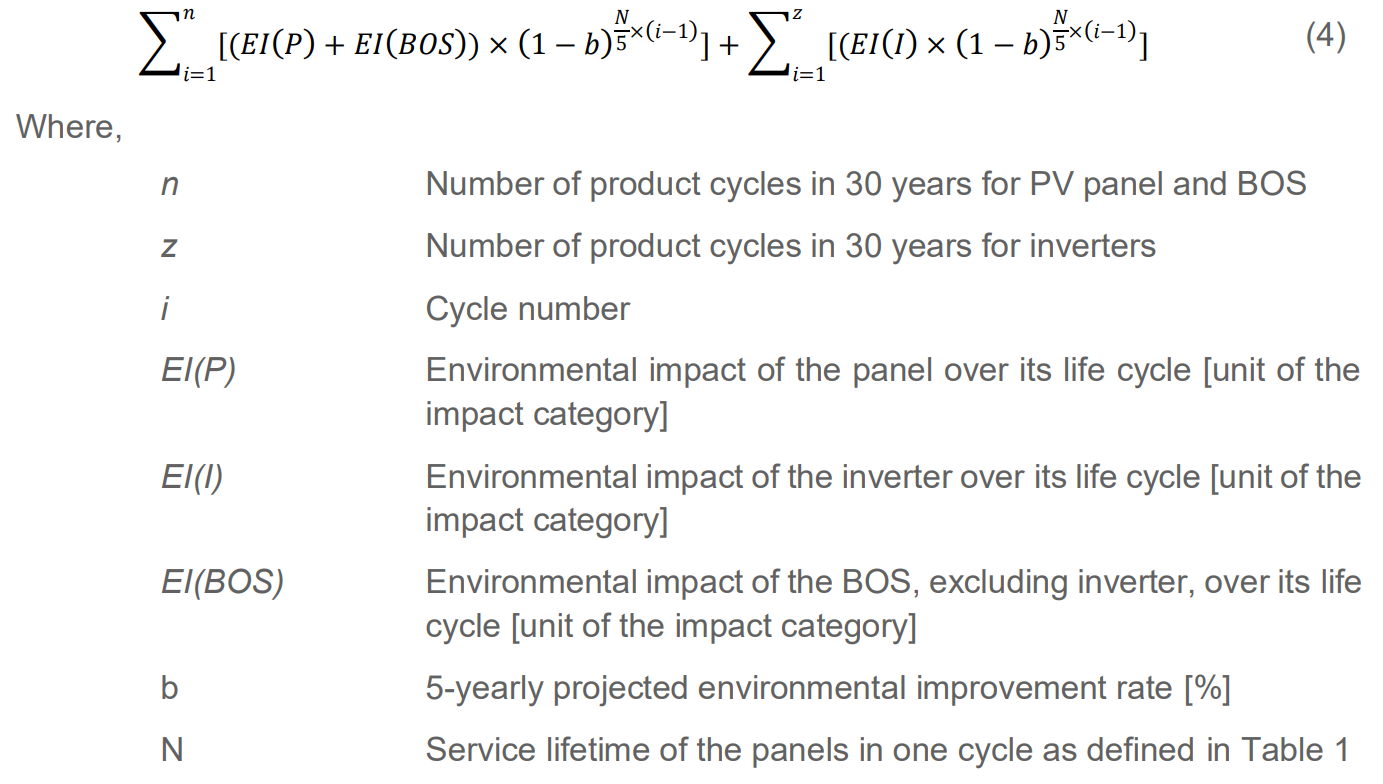

Equation 2 includes b, the 5-yearly projected environmental improvement rate (in %), which

is

expected to be

around 5% every 5 years. With equation 2 we calculate the total carbon footprint associated with the used PV

system over 30 years. With equation 1 we calculate the total electricity generated over 30 years. We compare

the performance by the functional unit g CO2-eq/kWh, so; dividing the result of the total carbon footprint

with the total electricity yield.